The Complete Guide to the Cage System of Layer Chicken Farming

Are you thinking of going into the business of poultry farming and you are considering using the battery cage system of housing?

If this is you, then you will find this article very useful.

To a large extent, chicken production, especially at the commercial level, heavily relies on intensive farming systems.

The common intensive systems of poultry housing are the battery cage system and the deep litter system.

In this article, I will dwell more on the battery cage system of poultry farming.

You will get to learn about the different types of poultry battery cage and their capacity.

You will also get to learn tips for choosing the best battery cage for your chickens.

That’s not all, I will also be sharing some amazing benefits of the battery cage system that will make you fall in love immediately.

Don’t worry, you will soon fall in love with this system of keeping chickens just like I have.

At the end of this article, I have shared some important links that will help you in your poultry farming journey.

If you really want to attain success, then click on the links and read the complete guide to poultry farming.

Now, if you are ready to learn more about the battery cage system of poultry management, let’s dive right in.

What is the battery cage system of chicken management?

The battery cage system (A.K.A chicken cage) is a type of intensive poultry housing system in which chickens are kept in compartment units.

This system is called the battery cage system because it involves the arrangement of similarly-looking cages in rows and columns.

Also, the rows and columns of the battery cage are closely knit together with the same dividing walls as the cells of a battery.

Even though most people associate a battery cage with poultry farming, you can also use it to keep other animals.

What differentiates the chicken battery cage from most other cages is that its floors slope from back to front.

The reason for this is so that eggs can roll from the back to the front of the cage for easy collection.

A lot of experts recommends the chicken battery cage, especially for egg production in a layers poultry farm.

Types of chicken battery cage system

There are several types of chicken battery cages and you can easily categorize them according to different criteria;

The different types of poultry cages can be classified according to the following categories.

- It could be based on the carrying capacity or number of birds in the cage

- Number of rows or decks the battery cage has

- The arrangement of the cages is also a criterium

- Also, the type of bird being reared determines the type of cage to use.

Now, let’s see each of these categories of chicken cages in detail

Types of poultry cages based on the capacity or the number of birds in a cage

For this group of cage systems, there are major two types

The multiple chicken cages:

This type of poultry cage houses from 2 to 10 birds. In most cases, they are only about 3 or 4 birds per cage.

Colony cages:

As the name implies, this type of chicken cage holds more birds than the multiple birdcages.

The colony cages hold more than 11 chickens per cage.

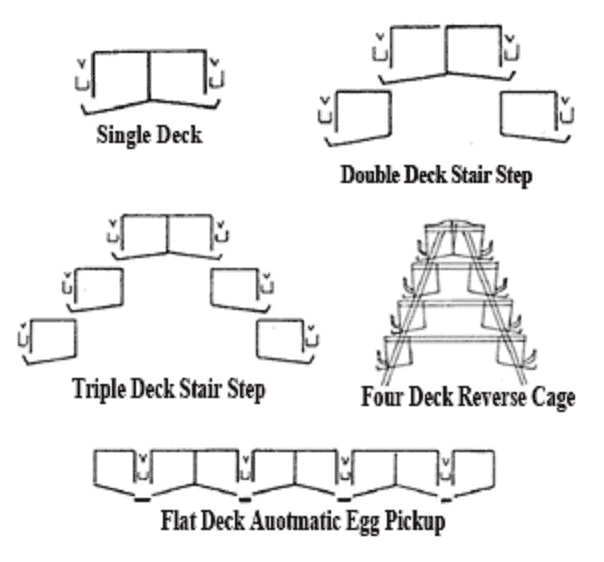

Battery cage system based on the number of rows

In this type of poultry cage system, the goal is to maximize the use of space.

As a result, the grouping here is based on the number of layers or levels the cage has.

Four main types of chicken cage systems exist based on the number of layers the cages have.

They are;

1. The single-layer battery cage:

This type of cage has only one layer. At best, you can only connect another set of cages parallel to this one. So, what you will have are two cages facing opposite sides.

2. Double-deck poultry cage:

As the name implies, this has two decks. One at the top and the second row on the bottom of the cage. With this cage system, you can save more space.

3. Triple-layers cage system

The triple-layers cage system provides even more space for you to keep more birds. With this cage system, you can have about three times as many birds on your poultry farm.

4. Four-tier chicken cage

For ease of operation and management, the four-deck chicken cage system is the highest for this category.

At this height, workers can still easily pick up eggs and do other daily activities without stressing muscle.

With four layers available for your birds, you can produce more chickens and eggs in this system.

It is a good option if you want to keep a very large quantity of birds but lack enough space to keep them.

5. Flat-deck poultry cage system

The flat deck poultry cage system is just like the single-layer battery cage.

The only difference this time is that the flat deck cage has more parallel lines of cages than the single layer.

Because of the arrangement of the battery cages in this system, workers cannot walk between cages to pick eggs.

As a result, the egg collection method for this system is automated.

Types of battery cage for chicken based on the type of chicken reared

If you are considering the type of chicken you want to rear on the farm then you should choose one of the following;

1. Brooder/chick battery cage

The chicken brooder cage, also called the baby chick cage system, is an important poultry farming equipment for raising baby chickens.

This type of cage is a kind of cage is suitable for raising chicks from 0-8 weeks.

It is easy to operate, suitable for large farmers poultry rearing, and leaves a clean raising environment.

The arrangement of the chick cages can either be as a single deck or double deck system.

This system has its feeders and waterers are outside the cage.

As a result of technologies in poultry farming, you can even have a nipple drinker for your birds from day-old.

Because this cage system is for chicks, you can spread newspaper sheets on the floor of the cage for the first 7 or 10 days.

This will provide the chicks with enough floor under their tiny feet.

In addition, you have to provide the chick feed inside the cage during the first week of age.

After the first week, they can pick their food from the feeding system attached to the outside body of the cage.

2. Grower poultry cages

The grower poultry cage house is used to grow egg-type birds from 9 to 18 weeks of age.

So, after keeping your chicks in the brooder cage for 8 weeks, in the 9th week, you can transfer them to the grower cage.

It is in the grower battery cage that you will prepare the birds for when they will start laying eggs.

Whether you are rearing growers chicken for commercial egg production or for your hatchery, this blossoming period as a complete hen is very important.

You need to put the birds in a better pen that will conserve the health and growth of the hends in this phase of their life.

The way you keep the birds at this stage (9-17 weeks) will reflect in the laying stages.

Therefore, you need to give the birds very close monitoring because of their volatile immune systems in this stage.

3. Poultry cage for Layers

If you are in the business of egg production or hatching, then you will agree with me that a layer bird is the essence of poultry farming.

After going through the chick stage safeguarding your birds with chick cages.

Then, what followed was accomplishing a splendid grower stage of uniform growth in grower cages.

By now, the birds are ripe to start laying their golden eggs.

It is at this stage of your poultry farming that you will see the efforts you invested in your chicks and grower birds.

You will start making money from your poultry business as the birds mature and start laying eggs.

However, you need a layer battery cage for this purpose.

Its biggest advantage is increasing egg production to 98%.

Besides that, with the layer battery cage, it is very easy to handle chicken waste and reduce disease transmission.

There are two types of layers of poultry cage;

- A-type of layers poultry-cage: The A type of battery cages can be 3-4 tiers high.

- H-type of layers chicken battery-cage: This type of cage can have up to 3-8 tiers.

4. Breeder chicken cage

Layer breeder cages are designed especially for breeding birds in the production of eggs for hatching purposes.

The breeder cages allow for a high stocking density of birds and require minimum labour to ensure clean hatching eggs.

In the centre of the cages is a reinforced perch offering the birds an opportunity to exhibit their natural behaviours.

So, both the male and female breeders have the reinforcement to perch on while in the cage.

In addition, there is a separation between the individual cages which ensures that males in different groups remain separate.

The breeder chicken cage has a cost-effective poultry feeding system that carries feed to the layer breeders consistently and evenly.

Also, the feed trough is deep enough to avoid feed losses while the birds perk on their feed.

Additionally, the egg collection system in the layer breeder cages can convey eggs to the longitudinal belt safely.

This makes hatching eggs cleaner: without dust and feathers.

The installation of nipple drinkers in this cage is at a different height.

This is to adapt to the water supply of hens and male layer breeders and provide fresh and clean drinking water.

The high degree of automation in this breeder cage system, including water and feed supply, egg collection and manure removal, leads to the high effectiveness of layer breeder cages.

5. Poultry cage for broilers

If you are thinking of growing broilers for meat production, then you should consider doing so with broiler chicken cages.

I advise starting with the battery cages for broilers since it provides a comfortable room for broilers.

In addition, broiler cages are a more economical and convenient way to grow chickens for meat.

With a broiler battery cage, you can provide a hygienic environment and reduce the death rate of broilers.

You can build your broiler battery cages in such a way that they have a perfect environment for the birds.

That way, you can ensure more cycles of broilers per year, which means more profits for you.

In addition, the high stocking density of broilers in the broiler chicken cages can save labour and resources significantly.

Advantages of the battery cage system of poultry production

The main advantages of battery cages for laying hens over alternative husbandry systems are

1. Battery cages help to boost the health of chickens

If you want your chickens to remain healthy over the period of rearing, then you must not overlook the use of battery cages.

Battery cages are a very good means of accommodating your chickens in healthy conditions that will boost their reproduction.

When I say battery cages, I don’t mean any kind of cage with a wire mesh floor and essential heating elements for brooding chickens.

Quality and superior battery cage go beyond that kind of simplistic design.

A good chicken cage is designed in such a what that it allows the chicken droppings to go through it.

When the poultry dung can drop freely, it is easier to clean it away from the chickens’ surroundings.

As a result, you tend to minimize the risks of diseases resulting from the attachment of chicken droppings to the cage.

Besides the safety Doing this will keep the chickens healthy and make chicken rearing a task worthwhile for the poultry farmer.

2. It helps to increases egg production in layers poultry

Besides safeguarding the health of your chickens, battery cages also help to increase egg production in layers.

A least, you and I can agree that when a chicken is healthy, it will significantly become more productive.

However, the reverse is the case for chickens that you rear in environments that do not boost their health.

A well-built battery cage increases the potential of egg production in chickens.

Recent estimations also reveal that 60% of eggs in products such as mayonnaise, sandwiches and cakes are from chickens reared in battery cages.

So, if you are going for the layers poultry business, then I will advise you to use battery cages to aid egg production.

3. Using a chicken cage reduces the cost of labour

The caging system of poultry farming reduces the cost of labour for the farmer.

This is because the chickens are well-organized and arranged in rows of cages having all the necessary facilities.

Each row of poultry cages has a feeding trough and a drinker that the farmer can easily fill.

Also, there is no need to wash the waterers and feeders every day as is the case with the deep litter system.

Since the birds are in cages far away from their feeding facilities, they cannot jump on the facilities to contaminate them.

Another beautiful thing about the cage system is that the poultry faeces drop in one place so that it is easy to clean.

In addition, eggs roll freely in the front of the cages where workers can easily pick them up without missing any.

Poultry management becomes easy with the cage system.

It reduces stress for the farmer and the need to employ many workers for the poultry farms.

4. You can rear a larger number of birds per unit area with battery cages.

With modern battery cages, you can rear a greater number of birds is per unit of an area.

That means battery cages save you cost in construction and help you maximize the use of whatever space you have available.

Many A-type poultry battery cages can accommodate between 60 and 128 chickens or more per unit, depending on the size and model you buy.

Therefore, it is rewarding to invest in poultry farming using chicken battery cages with a high capacity for accommodation.

5. Chicken cages are affordable to construct

Even if you are just starting your poultry farming business, you will find that poultry battery cages are quite affordable.

Besides being affordable, they are also durable and suitable for all egg-laying chicken types.

The battery cages are durable because the wire mesh is made of galvanized iron that prevents rusting.

For poultry farmers who have been using other rearing methods, you may consider giving the caging system a trial.

It is less expensive, more efficient and very effective.

So, to have a sustainable poultry farming business, I will advise you to go for the modern poultry battery cages.

6. The caging system facilitates correct maintenance of records

Because of the degree of organization in the poultry cage system of housing birds, it is easier to maintain correct records.

You can even arrange birds according to their age on the farm, or based on the hatchery they came from.

This system also makes it simple for you to know in a glance the number of sick birds on the farm and the egg production capacity of the farm.

Being able to maintain records easily is important to help make a forecast for the poultry farm.

You can also efficiently estimate inputs and avoid errors in your balance sheet.

7. Helps in identifying poor producers and prompt culling

With the cage system of layer chicken farming, it is easy to identify birds that are underperforming.

If it were in other systems of poultry farming, it may be difficult to identify which birds are not laying eggs properly.

Also, the cage system helps you to minimize the spread of diseases on the poultry farm.

So, it is easy to control parasitic diseases like coccidiosis and worm infestation.

You can easily identify those underperforming birds for treatment so as to boost their immune and reproductive system.

8. It helps in the production of clean eggs

One of the features of the chicken cage system that I admire so much is the production of clean eggs.

Seriously, customers like it when they don’t need to buy eggs with a lot of chicken faeces on them.

First, the sight of chicken droppings on eggs is irritating to most buyers.

Secondly, when those chicken droppings dried on the eggshell, they may harbour bacteria.

These bacteria may enter into human food when cracking the eggshell and contaminate it.

So, to avoid producing dirty eggs that your customers will not like, it’s time to switch to the battery cage system.

9. The poultry cage farming system prevents wastage of feed

It’s well known that about 70% of the cost of poultry farming goes into the purchase of feed for the birds.

As a result, every poultry farmer must do all they can to minimize the cost of feeding the birds.

Even though battery cages protect the birds and have other benefits, they also help the poultry farmer to minimize feed spillage when feeding chickens.

This is achievable because the cages are designed with standard accessories for holding food and water.

What makes it more interesting is that the feeding accessories holds just about the amount of feed the birds need daily.

This implies that you can adequately measure the feed consumption rate of the birds.

Also, you can estimate the amount of feed each bird needs to attain the market size and weight you desire.

Disadvantages of the chicken cage system of poultry production

While I was still in elementary school, my teachers told me that anything that has advantages also has disadvantages.

But in the case of poultry farming, the disadvantage of battery cage systems are quite small.

Some of the disadvantages are;

- The lack of physical and psychological space for the hens,

- Lack of exercise resulting in a higher incidence of metabolic disorders,

- Limitation of nesting opportunities resulting in severe frustration for many birds each time an egg is laid,

- The lack of dust bathing opportunities which, although not a severe disadvantage, should still be charged to cages,

- Also, a lack of other behavioural opportunities which again seem not to be a severe disadvantage and which await further elucidation, and

- A higher incidence of foot lesions.

Tips for choosing a good poultry battery cage

- Consider the dimensions of a cage so as to give the chickens enough space in the cage.

- Choose a cage with durable feeder trays. Types of feeders for battery cage includes aluminium, PVC, wood and plastic.

- Make sure you the cage is fitted with drinkers. Types of drinkers include nipple drinkers, PVC and so on

- Ensure that the cage is made of durable mesh. Types of materials for the poultry cage are galvanized iron and non-galvanized iron.

- The number of birds per compartment of the cage should be 4-6 birds.

- You can choose between buying an imported poultry cage or a locally fabricated chicken cage. You can also choose between manual, semi-automated and fully automated cages. It all depends on your farm size and the available capital for running the poultry farm. However, foreign cages and automated cages may be more expensive especially for beginners with small capital.

Other important specifications of the layer breeder cages system are shown in the table below.

Conclusion and Recommendation

Wow! It has been an interesting guide, hasn’t it?

I believe by now you already know how to go about using the caging system of poultry farming.

You have learned about the different types of battery cages and their capacity.

Now you know the benefits of using the cage system of poultry housing.

Moving forward, here are some important articles that will guide you to success in poultry farming.

- The Complete Beginners Guide to Poultry Housing Systems

- How to Construct a Good Poultry House

- 8 Unusual Reasons for High Poultry Mortality

- How to reduce poultry mortality and make more profits

- Poultry Farming For Beginners – A Complete Guide

- Fundamentals of Keeping Poultry Commercially

If you found this article helpful, please click on the social media icons on your screen to share it with others.

Don’t forget to drop your questions in the comment section below.

I reply to every comment, so keep them coming.

If you need help setting up your poultry farm, send an email to [email protected] and I’ll respond to you immediately.

Cheers.

Great work. It is going to help me a lot. Am grateful.

You are welcome

Thanks for the good work you are doing to help some of us who are planning to start the layer business and may God reward you in abundance.

Please I would like to know the name of the vaccines or medication to give the layer chicks according to their stages ei. from brooding stage, grower stage and layer stage.

Hope to hear from you soon.

Thanks

Sure, will work on that as soon as possible.

Nice work. It is very explicit and at the same very detailed. Well done!

Thanks for the compliment. I’m glad you found this guide for layer chicken farming very helpful.

I appreciate your work

Thank you very much, Peter.

Hi. Great article. I tried to join your WhatsApp group but it’s full.

It’s open now.

A great article… good job in presenting ‘just the facts’. As your teacher said, “there are advantages and dis-advantages’ with every decision. You laid them both out pretty well with your discussion. The final decision is left up to the owner. The ‘personal opinion vs. the technical implementation’ will be different with any two people that consider poultry farming.

Exactly. 100%

Battery cages are cruel. You are a selfish human that only cares about money.

Wow! Really? I hope you don’t eat bread and eggs because that places us in the same category.

battery cages are cruel and harmful to animals

Hola exelente información es uno de mis sueños y me gustaría estar preparados para realizar mi sueño que no es muy lejos exelente

Impresionante!! Espero que tus sueños se hagan realidad. Juntos, garanticemos el Hambre Cero en el mundo.